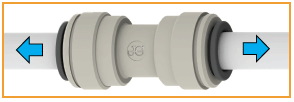

Polypropylene Speedfit to Speedfit Shut Off Valve is available in: 1/4″, 3/8″, 6mm, 8mm, 10mm, 12mm.

John Guest offer the widest range of push-in fittings, tube and other fluid control products for drinks dispense and pure water applications.

The world’s first food quality push in fitting, the John Guest range is now over 800 items strong and provides the quickest and most effective of installations.

Pushing the tube into the fitting is all that is needed to produce an instant but permanent leakproof connection. The fittings are just as easy to disconnect and re use without the need for replacement parts.

The products in this catalogue are produced in FDA approved materials making them especially suitable for potable liquids. Selected items can also be used for inert gases such as CO2.

Description

All the fittings from the shut off valve PP serie are produced in polypropylene, which has the advantage over acetal resin of being chemically more resistent.

The valves are used in water systems for food consumption

The shut off valves can’t be used for compressed air systems, inflammable gasses, kerosene, and other flammable materials.

Max temperature and pressure for use

10 bar at 20°C

4 bar at 60°C

Minimum temperature 1°

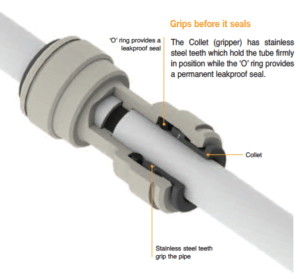

How Super Speedfit works

To make a connection, the tube is simply pushed in by hand; the unique patented John Guest collet locking system then holds the tube firmly in place without deforming it or restricting flow.

Materials of construction

Super Speedfit fittings are made up of three components:

Bodies are produced in an acetal copolymer or polypropylene.

O-Rings are nitrile rubber or EPDM.

Collets are produced in acetal copolymer or polypropylene with stainless steel teeth.

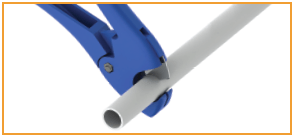

How to make a connection:

Cut the tube square and remove burrs and sharp edges. Ensure the outside diameter is free of score marks. For soft or thin walled tube we recommend the use of a tube insert.

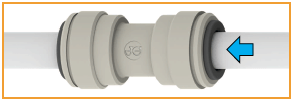

Push the tube into the fitting, to the tube stop.

Pull on the tube to check it is secure. Test the system before use.

To disconnect

Push in collet and remove tube. To disconnect, ensure the system is depressurized, push the collet square against the fitting. With the collet held in this position the tube can be removed.

Features

- Durable polypropylene shut off valve with EDPM O-Ring offers high chemical resistance

- Integral 1/4 turn isolation valve

- Instant push-fit connection and leak tight seal

- Connect, disconnect and reconnect in seconds without tools

- No scale build up improves performance and equipment lifespan

- Superior flow characteristics

- Suitable for potable liquid, intermittent hot water, water treatment and purification applications. Not suitable for compressed air, vacuum, explosive gases, petroleum spirit or other fuel or heating systems.

- Compatible with LLDPE or soft metal pipe/tubing

These 1/4″ Shut off valves are made to shut off the water flowing from upstream of the system. They must be used with the handle either turned fully on, or fully off.

Don’t use this product

- Half open or half closed to control water flow

- As faucet at the end of a water line

- Without having the tube inserted, or without having sealed both ends properly

Available sizes

PPSV040808W 1/4″ – 1/4″

PPSV041212W 3/8″ – 3/8″

PPMSV040606W 6mm – 6mm

PPMSV040808W 8mm – 8mm

PPMSV041010W 10mm – 10mm

PPMSV041212W 12mm – 12mm