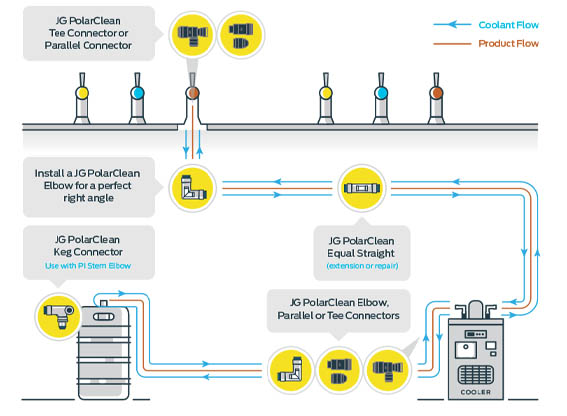

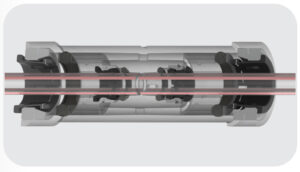

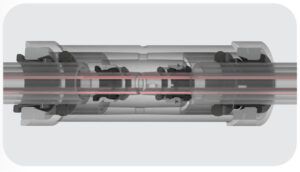

State-of-the-art push-fit tube-in-tube technology

Designed to overcome the detrimental effects on beer quality caused by traditional contact cooling systems, JG PolarClean beer dispensing connectors optimize draft quality, with its exceptionally efficient temperature conditioning within the beer line .

Extra cold. Extra clean. Ultra simple.

Our pioneering JG PolarClean push-in-tube connectors for beer dispensing improve beer conditioning and ensure a perfect pint every time.

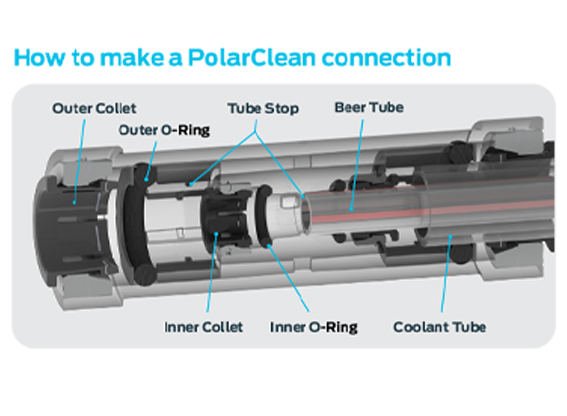

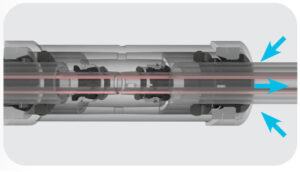

How to make a “tube – tube” joint

For transparent connectors

- 1. Push beer tube up to tube stop. Visually confirm correct tube positioning and pull to check connection is secure.

- 2. Push the coolant tube up to the tube stop. Visually confirm correct tube positioning and pull to check connection is secure.

- 3. Connect beer supply and check for leakages.

- 4. Connect coolant supply and check for leakages.

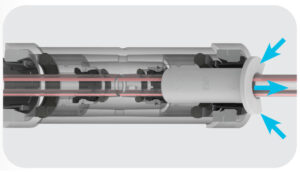

How to disconnect

- 1.Ensure both beer and coolant lines are depressurised. Push and hold the outer collet square against the face of the fitting whilst withdrawing the coolant tube.

- 2. Fit the Coaxial Collet Release Tool (NC2654) over the beer tube and slide into the Coaxial Connector until square against the inner collet. Depress the inner collet whilst withdrawing beer tube.

- 3. Remove Release Tool.

Note: For non-transparent coaxial connectors the beer tube passes through the connector without interruption.

piece available

JG PolarClean Parallel Connector 3/8″ × 3/8″ × 1/2″ NC2546