Commercial reverse osmosis ideal for large water demands.

The machine is ideal for:

- Bars and restaurants

- Breweries

- Pubs

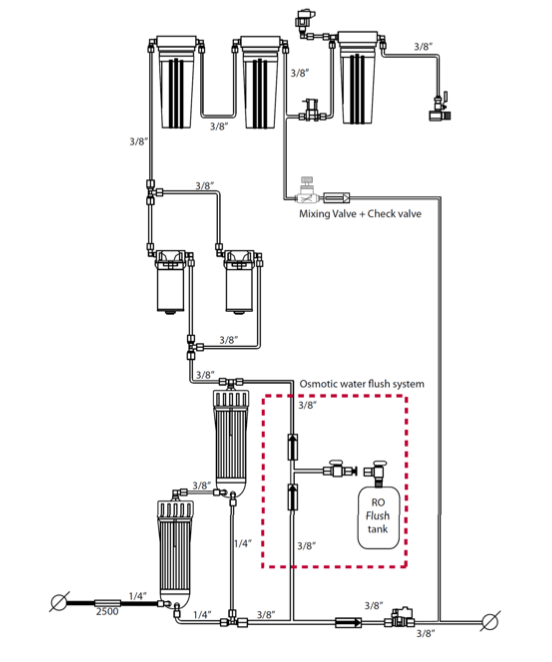

The machine is equipped with 2 membranes of 600 GPD supported by 2 booster pumps of 24 VDC and 2 storage tanks to serve the flushing of membranes. In this way the system is able to rinse the membranes with osmotized water in order to improve the performance of the machinery.

Before the membranes the water is filtered through a 3-stage system that includes a 5 micron sediment filter, a carbon GAC derived from coconuts and a 10 micron filter carbon block derived from coconuts.

Components:

- 2 membranes 3213 – 600 GPD

- 2 booster pumps 24 VDC

- 5 micron sediment pre-filter in expanded polypropylene

- GAC filter with coconut

- Filter Carbon Block coconut 10 microns

Connections:

- Water inlet.: 3/8″

- Discharge: 3/8″

- Production: 3/8″

Technical data:

- Power supply 220 VAC. – 240 VAC/50 Hz

- Water production: 200 lt/h

- Max recommended production: 200o lt/day

- Weight: 22 Kg

- Inlet pressure: 1 – 4 bar

- Inlet temperature: 2 ºC – 40 ºC

Dimensions:

- Height: 800 mm

- Width: 400 mm

- Depth: 260 mm

CHARACTERISTICS FILTRATION SYSTEM 20″

Sediment prefilter

5 μm expanded polypropylene cartridge.

– Retention of suspended particles.

Prefilter carbon GAC

Granulated active carbon from coconut shell.

-Retention of odour and taste-generating substances and particles. Retention/reduction of free chlorine in water. Reduction in the amount of organic compounds, trialometans and DQO.

Carbon block pre-filter

Active carbon granulate with extruded coconut shell. Retention of substances and particles that generate odors and flavors. Retention/reduction of free chlorine present in water. Reduction of the amount of organic compounds, trialometans and 10 μm filtration cod. .

Membrane

Membrane osmosis 2 type units: 3213 by 600 GPD

Self-cleaning

When the request ceases, the cleaning tank is filled to direct this water towards the membranes, thus carrying out a rinsing of the membranes with osmotized water.

Hydraulic scheme:

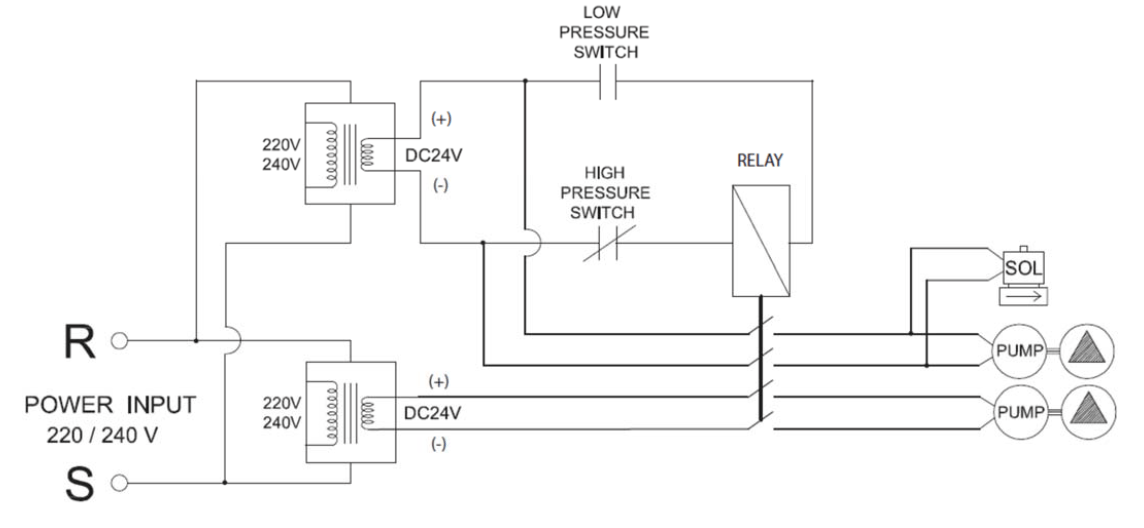

Wiring diagram: